Product introduction

- Product introduction

- Original apparel

Original apparel

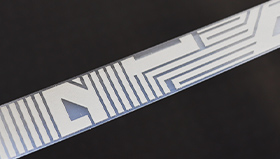

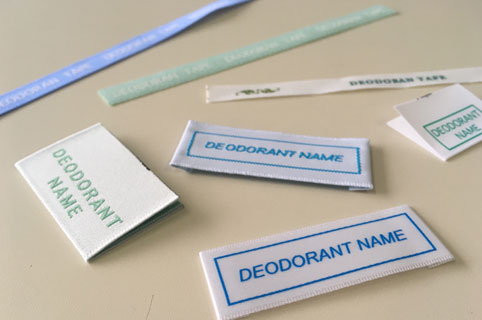

DEODORANT label®・DEODORAN tape®

Deodorant label® has superior deodorization and antibacterial effect. This can be applied to all kinds of materials, including woven labels and printed labels.

These are film laminate deodorant labels and deodorant tape with superior deodorization and antibacterial effects.

This kneads silver ingredients and fine inorganic particles that reduce bad odors by adsorbing and neutralizing bad odors in proximal spaces into a special resin and makes this into a film, which is then laminated to the back of woven labels. By broadening the contact area with gas using fine particles and evenly dispersing these inside the resin and thinning it out, deodorization and flexibility are simultaneously assured.

Also, this can be applied to all kinds of materials, including woven labels and printed labels without affecting the texture of the material.

Furthermore, because the ingredients are kneaded into a film, they are not lost even with washing and dry cleaning, allowing their function to be maintained.

DEODORANT label®・DEODORAN tape®Deodorization Mechanism

This safe and outstanding deodorant made from inorganic substances adsorbs a variety of bad odors and neutralizes and deodorizes into odorless substances.

DEODORANT label®・DEODORAN tape®Deodorizing Effect

Conventional labels

- Conventional labels in containers measured with detector tube

Deodorant labels

- Deodorant labels in containers measured with detector tube

※When deodorant labels and deodorant tape are attached to actual products and used, their performance is affected by product material, type of bad odor, size of space where it is left, temperature, humidity, and other factors.

DEODORANT label®・DEODORAN tape® antibacterial mechanism

The positive silver ions suppress the proliferation of staphylococcus aureus that adheres to labels and tape and prevent the generation of odors.

Example of DEODORANT label®・DEODORAN tape® use

Can be attached to clothing, but also hats and shoes, bags, stuffed toys, and others.(The part indicated with a red line is the part where the label is attached)

DEODORAN tape®Description Video

- Standard Version

- School Version

- Business Version

TRANS RAPIER®(Woven Thermal Adhesive Emblems)

Premium Thermal adhesive emblems that has a feel of substance created by weaving, and enables refined expressions embroidery could not achieve.

We used the finest woven patterns, specialty yarns and processing techniques traditionally fostered by our brand label to achieve this luxurious woven material. Because these are thermal adhesive, the worn garments remain soft to the touch and comfortable.

It can be easily design modify and change by "On-demand" which means trans rapier® is no necessary mold and stencil. Correspond consistently from more attractive design art work until processing mark and support of adhesive processing.

Features of TRANS RAPIER®(Woven Thermal Adhesive Emblems)

- 1.Soft to the touch both on the front and back sides

-

Because the cut edges are tapered, the edge structure remains smooth and does not easily get caught or peel off.

The back surface does not get rough like embroidery, not ruining the texture and keeping the softness.

- 2.Corrugation does not damage the garment material

-

No need to make a needle go through the material as in embroidery, causing no damage.

Also the mark doesn't warp because it's a polyester fabric which is less shrinkage.

- 3.Easy processing and consistent finish

-

Thermal adhesion is used so that the processing time is shortened compared to embroidery. For embroidery, different factory may mean different finish, while Trans Rapier® has consistent finish, exactly presenting the desired image no matter where they are processed.

ORDER MADE TEXTILE

Making the most use of our design know-how which was nurtured as a brand label manufacturer, our textiles are brimming with originality.

ORDER MADE TEXTILE system fully supports customers throughout the process, from simulating textile patterns and colors, to producing the textile.

ORDER MADE TEXTILE system can be exploited to relieve the stress of customers having difficulty in searching for textiles, and in deciding on patterns and colors for their textiles, and so providing products which satisfy the customers requirements.

This new system allows customers who previously could not proceed smoothly due to the excessive cost involved in prototype development work and of final production lots, to now be quickly presented with a final product image of the textile conceived for confirmation, before weaving just the desired quantity.

Features of ORDER MADE TEXTILE

- 1.We can deal with the high density weave of fine lettering and designs etc

-

Being capable of creating textile patterns from scratch, we are able to produce a textile to suit a customer's requirements. We are also capable of dealing with the high density weave of fine lettering and designs etc. (maximum width; 110cm) We also deal with low quantity orders.

- 2.Abundant Multiple Colors of CATION DOMTEX® and this solves the sublimation problem

-

CATION DOMTEX® is the 418 color options, up to 8 colors can be chosen in any one design.

And it solves not only a problem of sublimation but also it has various fastness at high level for washing, dry cleaning, friction, chlorine bleaching and hot press.

- 3.Cut Processing

-

Upon request from customers, using a laser-cutting machine, delivery is possible as cut parts. (size able to be processed: 600mm×1200mm) It is also possible to insert a logo or symbol within the designated area of the cut parts.

- 4.Adding Functionality

-

Upon request, extra functionality can be added to a product, such as waterproofing, antifouling, dust proofing, deodorant, and security features.

Use example

- Shoes

- Temple Stamp Books

- General Goods

- Bags

- Hats

LUMINESCENCE PLATE

Luminescent plate with Japan’s highest level of “Ultra-high luminance emission performance,” greatly exceeding JIS standards.

- 1.Achieving highest degree of luminance

- With even a short time of exposure, high brightness is emitted for a long time.

Even in darkness, it is possible to distinguish the presence of others and items and make others aware of your presence.

- 2.Thin and lightweight

- It is easy to attach to walls, etc. because it is light and can also easily be attached to relatively high spots.

- 3.Abrasion resistance

- The product’s surface is plastic, so it is resistant to scrapes and other types of abrasion.

- 4.Power source not required, no maintenance required

- No power source is used, so it is an eco-friendly product mindful of the environment.

Performance

Excitation conditions: Normal light fluorescent lamp D65 200 Lux illumination for 20 minutes

Measurement: Phosphorus light brightness 20 minutes after illumination is complete

Luminance meter: Konica Minolta LS100

| After 20 minutes | ||

|---|---|---|

| JIS Z 9107 Minimum phosphorus light brightness |

JA | 24mcd/m2 |

| JB | 50mcd/m2 | |

| JC | 100mcd/m2 | |

| JD | 200mcd/m2 | |

| HIGH BRIGHTNESS LUMINESCENCE PLATE | 345mcd/m2※ | |

| Illumination | After 20 minutes | 200 Lux/20 minutes illumination (Fluorescent lamp D65) |

|

|---|

JIS standard: JIS Z 9107 safety sign-performance type, performance standard, and test method

※Phosphorus light brightness data Our company’s study(this is the measured value and not guaranteed value)

luminance Phosphorus light brightness 10 times compared to our company’s conventional

Use example(left photo is under normal conditions and right is emitting light)

- under normal conditions

- emitting light

- under normal conditions

- emitting light

- It allows escape routes to be seen during sudden blackouts, ensuring safety

- Identify position of fire extinguishers in natural disasters, blackouts, and other emergencies

- Determine the whereabouts of items you want to reach even in darkness

- Clearly show the way during blackouts and at night

- Identify cellphones, key holders, and other small items

- Distinguish doors in darkness and avoid collisions in emergency evacuations

Luminous film

Luminous materials are materials that absorb natural light, artificial light, and other forms of light energy and emit this as light in darkness.

We make it possible to add this function to printed labels and woven labels. Transfer film type luminous material is used. This is characterized by no irregular color and high brightness. Sunlight, fluorescent lamps, and other light is absorbed, accumulated, and emitted in the form of light for certain amount of time in darkness.

Transfer type luminescent materials have a very soft feel due to the use of a urethane base. These are rolled films, so they allow for sequential line expressions. In combination with retroreflective material, visibility improves in darkness.

Luminescent ingredients are safe materials with high initial brightness that do not contain any radioactive substances and their diminution over time is relatively slow.

Afterglow intensity measurement results

Measurement conditions:22 W fluorescent lamp with 40 cm vertical beam illumination for 20 minutes, followed by being left in a dark room.

Afterglow intensity data

| Time(minutes) | Afterglow intensity(mcd/m2) | (Reference)JIS Z 9107(safety signboard)standards |

|---|---|---|

| 0 | 613 | |

| 10 | 57 | 50mcd/m2higher |

| 20 | 30 | 24mcd/m2higher |

| 30 | 19 | |

| 40 | 17 | |

| 50 | 13 | |

| 60 | 10 | 7mcd/m2higher |

Safety signboard JIS standard level afterglow brightness is present.

- Afterglow brightness curve

Use example

※This photograph is of the luminescent material emitting light in darkness.

RETROREFLECTIVE MATERIAL(COLORFUL REFLECTOR)

Retroreflective material is used but allows for a variety of coloring and has good design and high brightness and visibility. Can be used in a variety of life situations at night with no sense of discomfort. Retroreflective materials are materials that have the property of reflecting light in the direction of the light that enters (incoming light). It is used in signboards that light up brightly by reflecting headlights when driving at night.

They can take on any color, so nighttime visibility is improved with high brightness at around 80 candela(※)with front brightness regardless of the color. (Reflected color becomes white)There are 3 attachment methods, including sewing, thermobonding, and pressure bonding, allowing for use in a variety of products and not just clothing.

※Candela(cd)are units of brightness of light emitted from a light source. The word originally comes from 1 candela being the brightness of a single candle. Candela refers to candles. Today, candela are an international unit defined accurately using light wavelength, output, etc.

Comparative photograph during the day and at night

- The day

- Night(Retroreflection)

Use example

Attachment method

| Sewn type(sewing) | Used by sewing laminate processed fiber materials, etc. to products as labels and tape. |

|---|---|

| Thermobonding type | This is a directly thermobonded type to materials like clothing. Rather than sewing to a body cloth, it allows for a uniform marking. Allows unification into a single product as in neck pieces and armbands. Reverse release paper is torn off and thermobonding processing is done, after which it is cooled and front protective film is removed. |

| Pressure bonding type(seal type) | Allows for bonding to clothing, metals, and plastics, among others. Reverse release paper is torn off and the item attached, after which the front protective film is removed. |

Individually controlled labels

"Uniforms, the face of companies, can end up in the hands of a third party via a leak or loss, resulting in misuse. Such incidents can also damage the social credibility of a company."

Designed seam tape

Nippon Dom's designed seam tape is a high quality printed seam tape with superior expression of design and reliable fastness and quality

Our unique printing technology allows printing on highly difficult seam tapes and adding functionality. We also give customers ease of mind in use in terms of high fastness and other quality factors.

*Designed seam tape is a tape used to prevent water from entering seams by heat-sealing sewn parts of waterproof clothing such as outerwear and down jackets. The base material and thermal bonding may or may not be compatible, so testing is required in advance.

We have met the seam tape print quality standards of GORE-TEX products. In addition, there are printing results in various brands, allowing for use with confidence.

Features of designed seam tape

- 1. Fine design expression

-

Fine design expression enabled by high quality printing enhances brand value.

- 2. Rich printing variations

-

In addition to normal printing, we also support printing using special inks to meet customer needs.

- 3. Safe and secure DOM Print

-

We have numerous results of printing brand name prints using silk screen printing, allowing for use with confidence.

Use examples

Recommended for linings such as those on clothing, caps, and shoes.

- For clothing lining sewn parts

- For cap lining sewn parts